The bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance.

Bending 18 gauge sheet metal into cylinders.

For example in one gauge system 18 gauge steel.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

Bend radii minimum bend sizes.

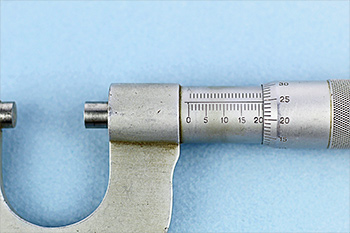

For example 18 gauge steel according to a gauge conversion chart is 0 0478 inch or 1 214 millimeter.

Most frequently expensive sheet metal bending tools called brakes are used to bend sheet metal but you can also complete this task without one.

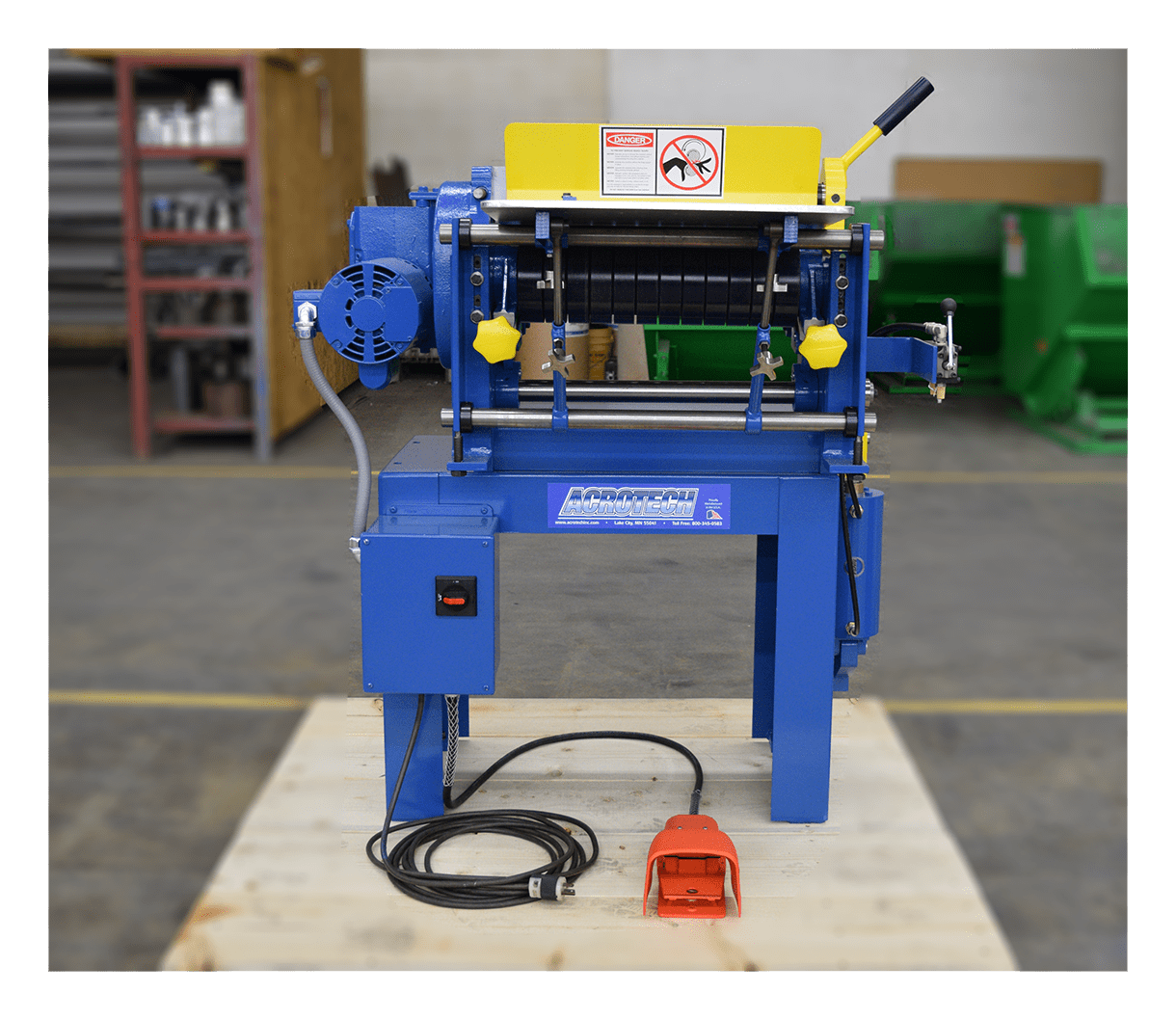

These precision engineered machines can bend up to 22 gauge stainless steel sheet metal 18 gauge steel or 16 gauge aluminum depending on the model.

Our custom sheet metal bending services can produce rolled sheet metal pipes and cylinders in diameters from 3 to 12 and beyond.

Make your own sheet metal break.

The gauge number 18 holds no relevance to the actual measurements.

Subscribe my channel for more new videos.

Best sheet metal brakes.

Chicago metal rolled products can produce full cylinders 360 or cylinder segments from curved sheet metal from 12 to 28 gauge.

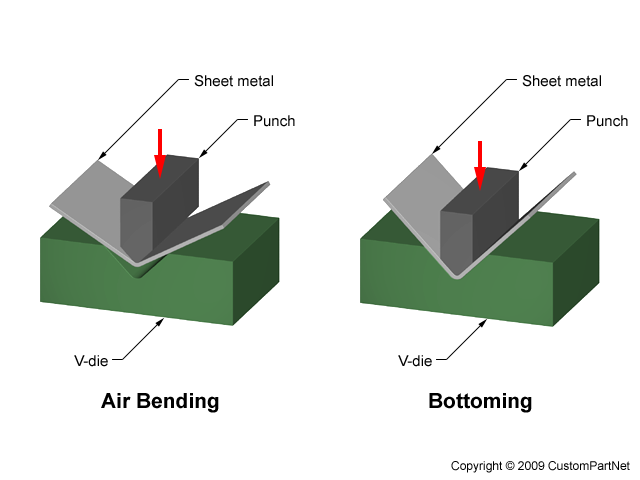

Sheet metal bending bending of sheet metal is a common and vital process in manufacturing industry.

The material thickness will be measured in decimal form not by the gauge number.

Sheet metal bending is the plastic deformation of the work over an axis creating a change in the part s geometry.

For dimension and more informat.

It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

Hello friends today i make a sheet metal bending tool.

There are several different gauge systems used today with specific gauge designations used for specific metal types.

From small 4 inch brackets to 48 inch wide engine pans there s an eastwood sheet metal brake for sale that will fit your project.

I hope you like this video.