Maziar ramezani zaidi m.

Conventional sheet metalworking process.

Also an attempt is made to locate the origin of isf.

It also includes various cold stamping die structure and process parameters various equipment working principles and operating methods and also includes new stamping techniques.

Sheet metal forming is a costly manufacturing process that is widely used in different industries.

There is usually not much change in the thickness of the sheet metal.

Advantages over conventional sheet metal forming.

Many small companies are required to manufacture curved products and shallow parts with fine details in a small lot size which leads to both a higher production cost per detail and a need for multiple tools.

Shear spinning is a process related to conventional spinning and is also known as flow turning or spin forging.

Note that for small quantities spinning is more economical.

The guerin process is a sheet metal forming process that uses a rubber die that flexes to force the sheet metal to take the shape of a form block punch.

Metal spinning also known as spin forming or spinning or metal turning most commonly is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part.

Because the process can be controlled entirely by cnc processes no die is required as is in traditional sheet metal forming the elimination of the die in the manufacturing process reduces the cost per piece and increases turnaround time for low production runs because the need to manufacture a die is eliminated.

A suspension system component or the like of an automobile is produced by performing press processing or other processing on a metal sheet such as a high tensile steel sheet.

In a conventional spinning operation the work is essentially formed by bending.

The guerin process is a sheet metal forming process that uses a rubber die that flexes to force the sheet metal to take the shape of a form block punch.

Metal spinning does not involve removal of material as in conventional wood or metal turning but forming moulding of sheet.

Conventional burring processing is performed by first forming.

In conventional sheet metalworking operations a what is the name of the tooling and b what is.

We just prepared you the pdf version of the sheet metal forming process you can download it here.

Cost comparison for manufacturing a round sheet metal container either by conventional spinning or by deep drawing.

In conventional sheet metalworking operations a what is the name of the tooling and b what is.

Conventional sheet metal forming process 4.

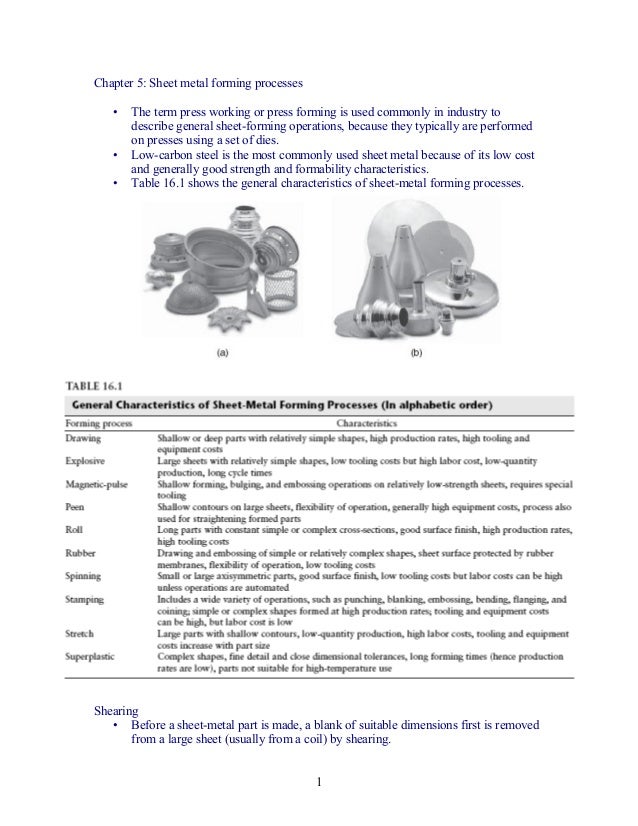

Sheet metal processing includes conventional methods such as cutting blanking blanking bending and forming and various process parameters.

Experimental modification of spinning but cannot consider history this section mainly describes the early developments before the first true isf patent 1993.