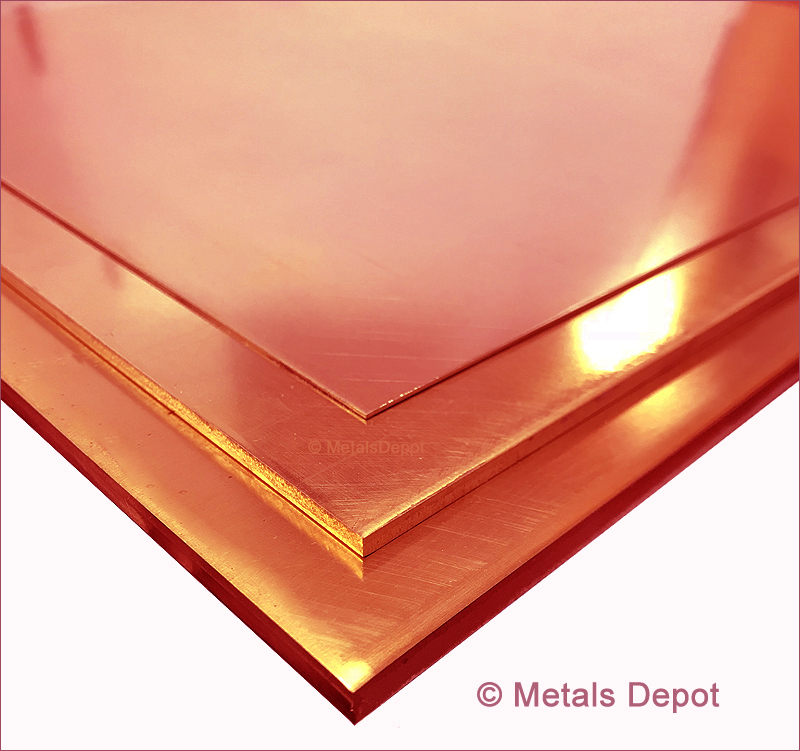

110 copper sheet plate is widely known for its architectural applications whereas the familiar green patina appearance is acheived when exposed to the elements copper sheets and plates have excellent hot or cold workability and is ductile when heated.

Copper sheet resistance thickness.

1 mil 001 inches thick.

All of our raw copper sheets are pure copper annealed dead soft with a smooth commercial finish manufactured to astm b152 alloy c110.

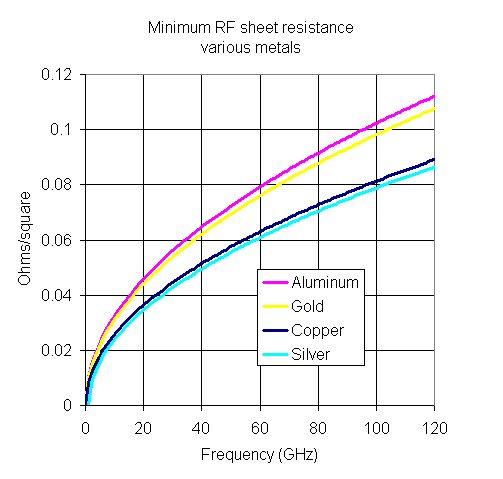

Sheet resistance often called sheet resistivity is a measure of resistance of thin films that are nominally uniform in thickness.

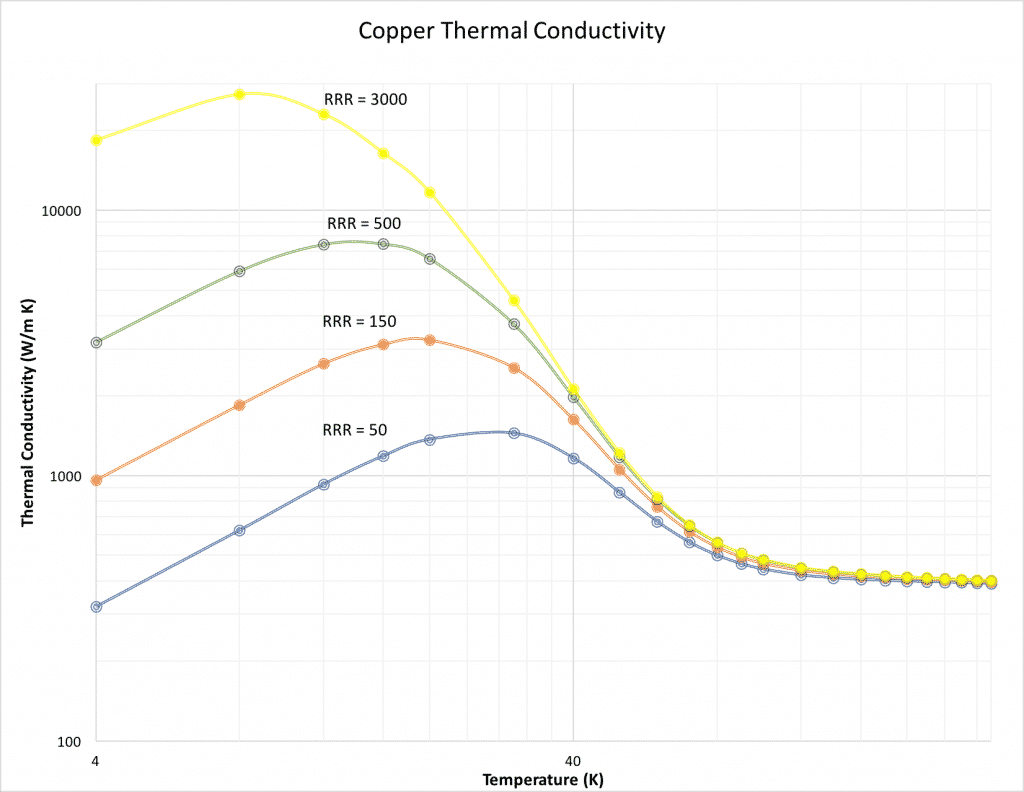

Copper sheets plates are also noted for their high electrical and thermal conductivity and good corrosion resistance.

You can tear.

One of few metals that doesn t need to be extracted from ore i e it is directly usable in its natural state copper exhibits excellent thermal and electrical conductivity good ductility and a natural resistance to corrosion.

This makes the sheet resistance of 1oz copper foil about.

Copper sheet and copper plate find use in a huge array of applications.

However due to corrections up to 0 3mm would be ok.

This is the origin of the very simple rule of thumb that.

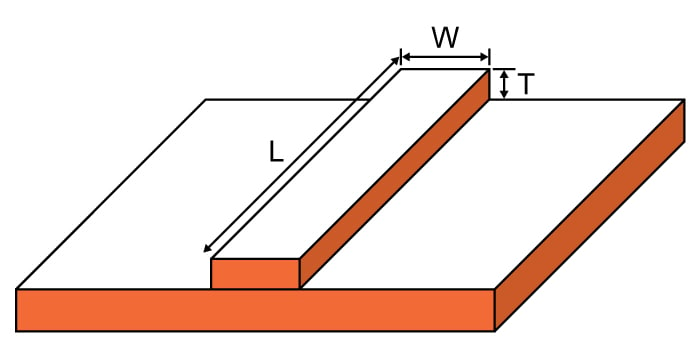

The unit mω 1 means mω per square shaped sample as for the same material the sheet resistance is always the same for a square sized sample with the same thickness regardless of its dimension.

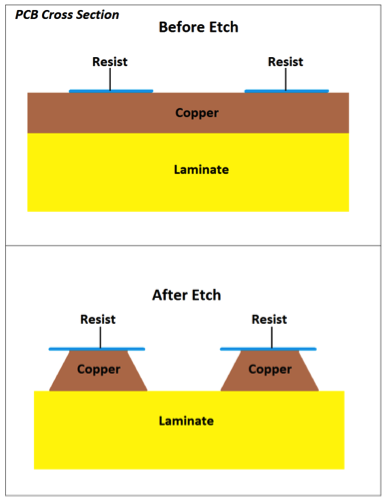

The thickness of 1oz copper foil is about 34µm or 1 4 mils.

This is very thin copper foil.

When the thickness exceeds 0 1 of the spacing between two needles after which sheet resistance doesn t apply.

The edge to edge resistance of a section of copper foil cut in the shape of a square depends only on the thickness of the foil and the bulk resistivity of the copper.

At what point do you stop multiplying the sheet resistance by the thickness in centimeters to arrive at ohms cm.

A beautiful and versatile metal copper has been utilized for thousands of years.

The sheet resistance of the electroless copper deposits from different plating solutions against plating time.

So 0 1mm for a probe head with 1mm needle spacings.

Copper sheet is a very workable and malleable form of metal high in electrical and thermal conductivity and provides excellent corrosion resistance.

A study of sheet resistance and thickness correlation.

It is approximately 1 5 times thicker than typical household aluminum foil and is easy to cut but also easy to wrinkle.

It is commonly used to characterize materials made by semiconductor doping metal deposition resistive paste printing and glass coating examples of these processes are.

For 1 ounce thick copper foil we showed the sheet resistance is 0 5mω sq.

The sheet resistance of 1 oz copper foil is 0 5mω square.

The ipc spec for copper bulk resistivity at 20ºc is 1 72µω cm.

Whether it s a thick film or thin film application shielding effectiveness is best calculated via sheet resistivity.